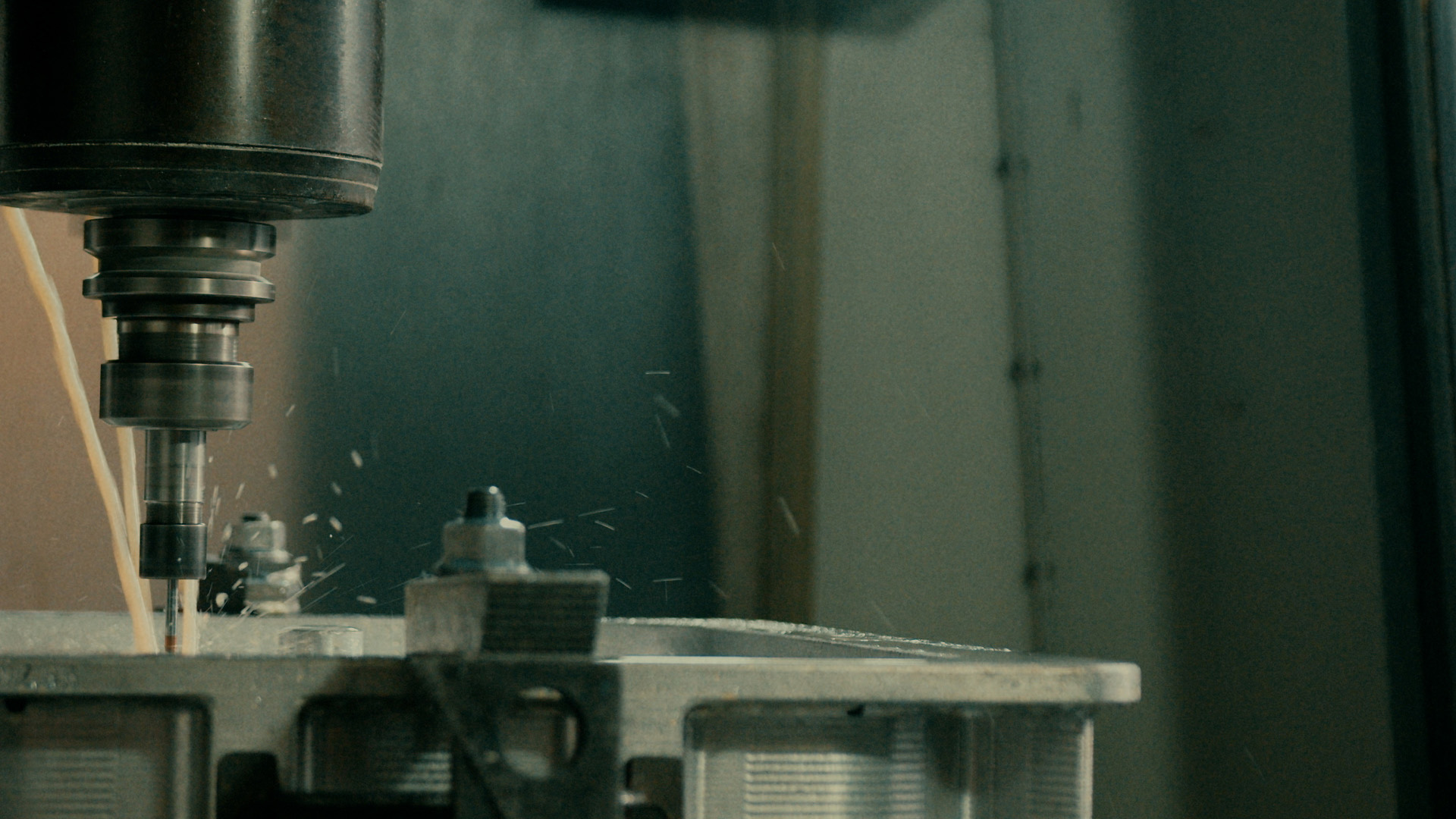

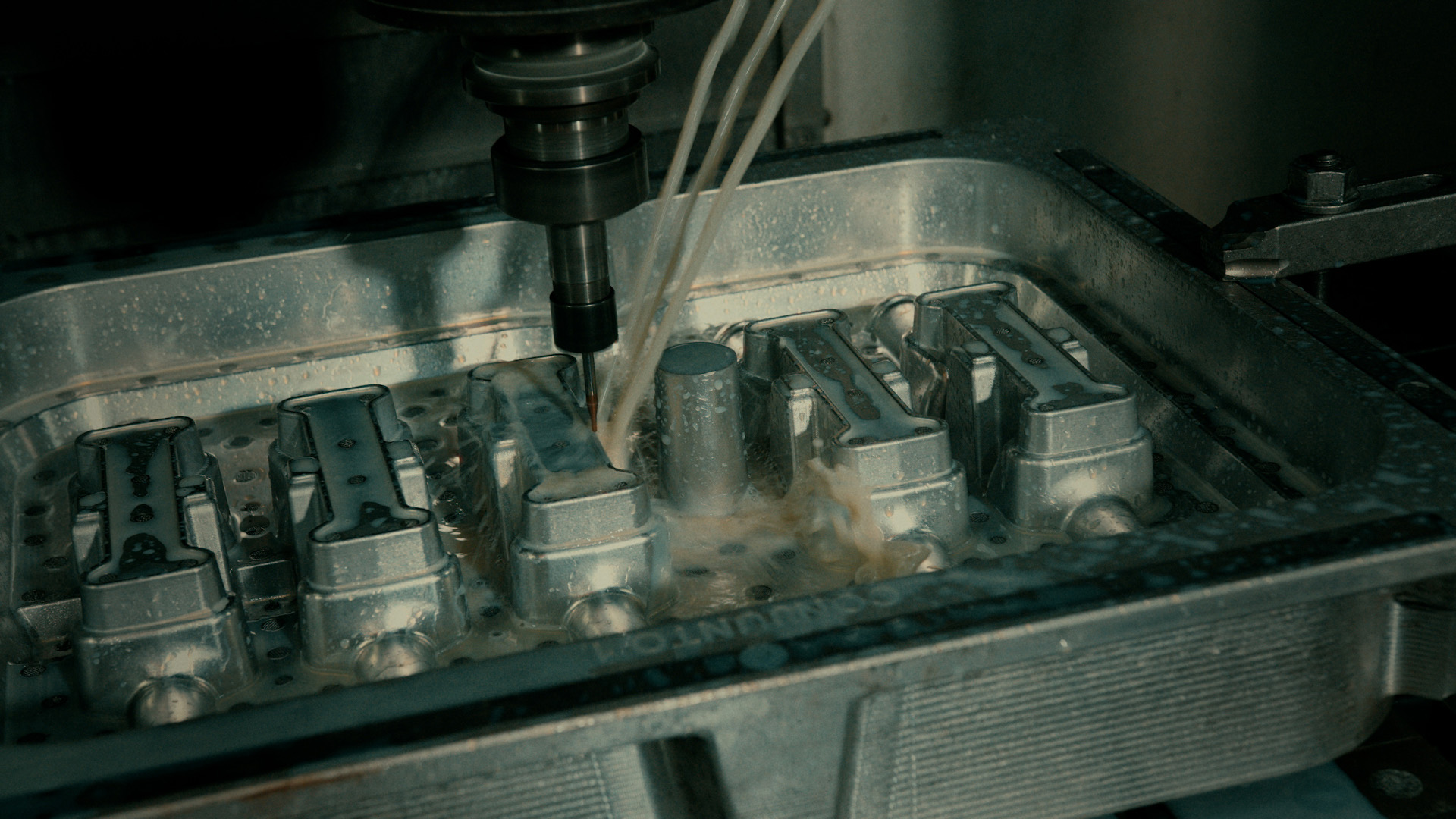

Gravity casting

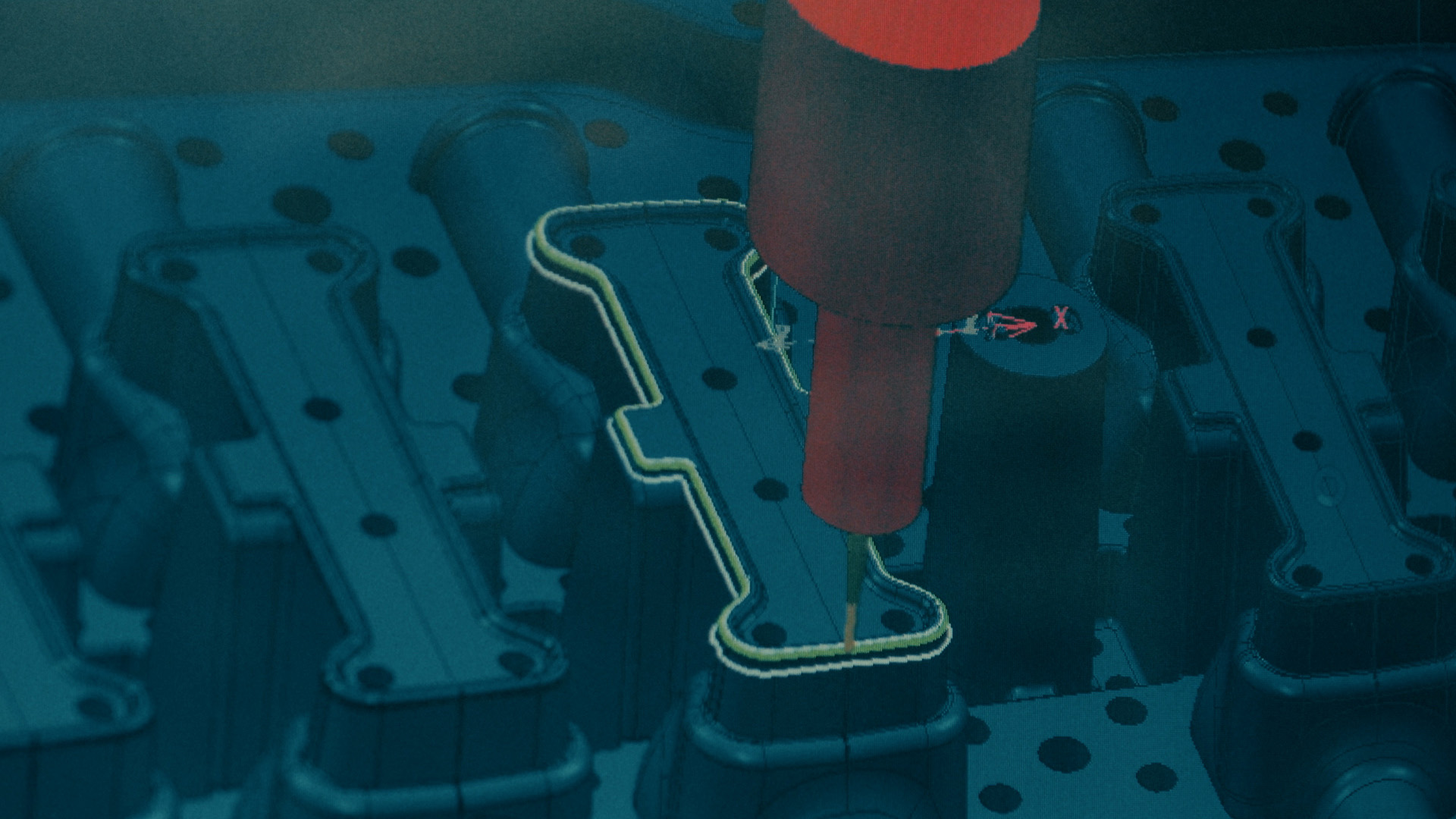

Volani Metais is equipped to produce cast parts using the state-of-the-art Cold Box process, featuring an Induction melting furnace and two crucibles for manufacturing ductile cast iron parts. Additionally, it has a natural gas furnace with a crucible for manufacturing non-ferrous alloy components. With these facilities, the company can produce parts ranging from 0.2 to 30 kg, maintaining the quality and precision that the demanding market has come to expect. The company also offers flexibility in accommodating low-volume orders.